Riding the wave of the Internet of Things and driven by maker culture, ultrasonic sensors have become a key tool in today's technology fields. These small devices, based on acoustic echo-ranging technology, play a crucial role in various industries with their non-contact measurement methods and outstanding precision. From the automation lines of industrial manufacturing to the reverse parking radar systems of automobiles and to the intrusion detection in the field of security monitoring, the applications of ultrasonic sensors are ubiquitous.

This article will delve into a series of ultrasonic sensors: the HC SR04, and Maxbotix, analyzing their working principles, performance characteristics, and real-world application examples. By comparing the specifications and conducting performance tests on four specific ultrasonic sensors (HC-SR04; EZ4 MB1040), our aim is to provide you with a comprehensive evaluation framework to help you choose the most suitable ultrasonic sensor for your specific application needs.

1. Introduction to Ultrasonic Sensors

Ultrasonic sensors are devices that utilize ultrasonic waves (sound waves with frequencies higher than the audible range for humans, typically above 20kHz) for measurement and control. They have a wide range of applications in the IoT industry because they can provide contactless, high-precision, and real-time measurements. In this section, we will introduce the basic principles and application fields of ultrasonic sensors.

1.1 Basic Principles

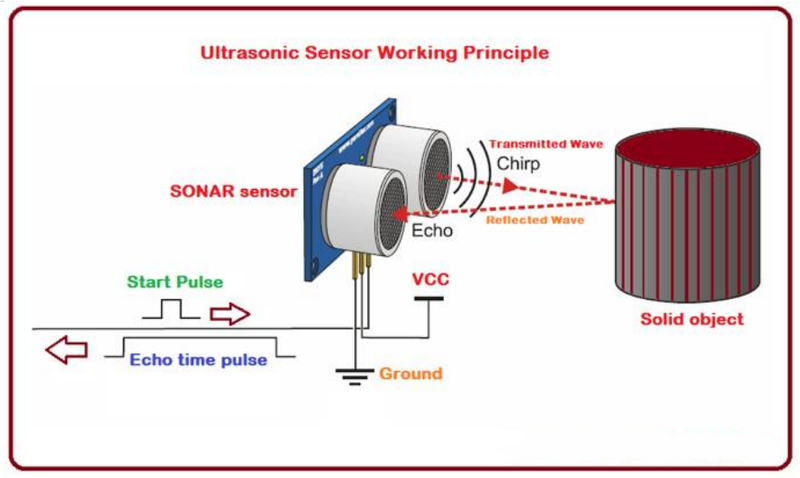

The working principle of ultrasonic sensors is based on the characteristics of ultrasonic wave propagation in a medium. A sensor typically consists of a transmitter and a receiver. The transmitter generates an ultrasonic signal, which then propagates through the air or another medium. When the ultrasonic waves encounter the surface of an object, they produce echoes that are captured by the receiver. By analyzing the propagation time or phase difference of the ultrasonic signal, it is possible to measure physical quantities such as the distance, speed, and direction of the object being measured.

The accuracy and measurement range of an ultrasonic sensor depend on its operating frequency and transmission power. High-frequency sensors can provide higher resolution but have a smaller measurement range; conversely, low-frequency sensors have a larger measurement range but lower resolution. Additionally, the propagation speed of ultrasonic waves in different media also affects the performance of the sensor.

Figure: Ultrasonic Sensor Working Principle

For more information on the principles of how ultrasonic waves measure speed, you can click on this article to learn more.

1.2 Application Fields

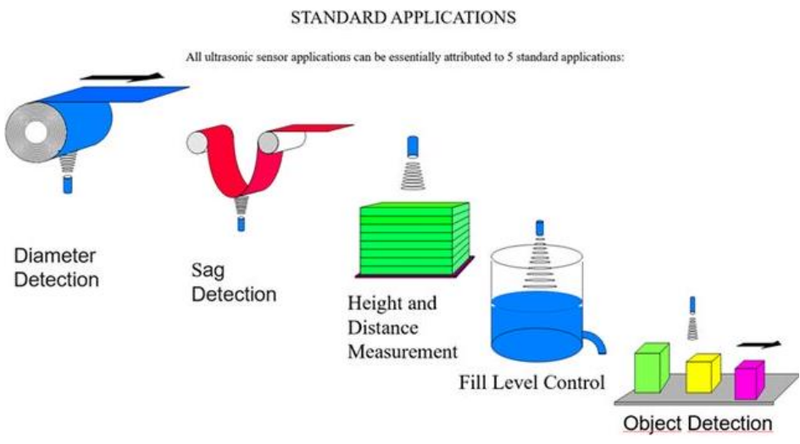

Ultrasonic sensors are widely used in the IoT industry, and here are some of the main application areas:

- Distance Measurement: Ultrasonic sensors can be used to measure the distance between objects, for example, in parking management systems to detect the distance between a vehicle and obstacles.

- Level Monitoring: Ultrasonic sensors can be used to measure the height of liquids, such as in reservoirs and oil tanks, to monitor liquid level changes in real time.

- Flow Measurement: By measuring the propagation time of ultrasonic waves in a fluid, the flow rate and volume of the fluid can be calculated, which is widely used in the flow monitoring of water, gas, and other fluids.

- Object Detection and Positioning: Ultrasonic sensors can be used to detect the presence and location of objects, for example in warehouse management and robot navigation scenarios.

- Structural Health Monitoring: Ultrasonic sensors can be used to detect cracks, corrosion, and other conditions in building structures, pipelines, and other facilities, providing early warning of potential safety hazards.

Figure: Common Application Scenarios of Ultrasonic Sensors

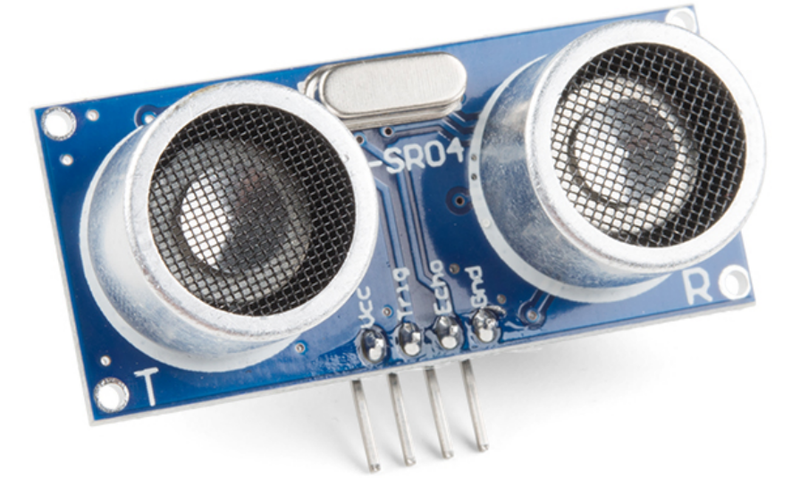

HC-SR04

The HC-SR04 ultrasonic sensor is a cost-effective sensor widely used in robotics, automation equipment, and other distance measurement scenarios. It has gained a strong position in the market due to its affordable price and impressive performance, making it particularly popular among beginners and DIY project enthusiasts.

Since its introduction, the HC-SR04 has become a classic in the field of ultrasonic distance measurement sensors. Its measuring range is between 2 centimeters and 400 centimeters, suitable for a variety of distance detection tasks. In terms of power requirements, the HC-SR04 operates on a 5V supply, making it compatible with mainstream development platforms such as Arduino and Raspberry Pi. In addition, the HC-SR04 sensor has low power consumption and a compact size, making it easy to embed in various devices. Therefore, this sensor is suitable for DIY projects and educational applications where precision measurement requirements are not extremely high, such as smart cars, object detection, and obstacle avoidance.

Figure:Ultrasonic Distance Sensor - HC-SR04

Maxbotix

Maxbotix is a well-known ultrasonic sensor manufacturer from the United States, famous for the research, development, and production of high-quality ultrasonic sensors.

The Maxbotix series of ultrasonic sensors are characterized by high precision, low power consumption, and strong anti-interference capabilities. These sensors can work stably under various environmental conditions, including adverse weather, high humidity, and high temperatures. In addition, Maxbotix sensors have low power consumption, making them an ideal choice for remote monitoring and Internet of Things (IoT) applications.

The price of the Maxbotix series of ultrasonic sensors is much higher compared to similar products, but their outstanding performance, precision, and reliability make them the preferred choice for high-end industry applications and institutions, such as industrial automation, environmental monitoring, unmanned aerial vehicles (UAVs), and more. These customers usually have strict quality requirements for sensors and are therefore willing to invest at a higher price point to ensure they receive products with exceptional performance.

Figure:MaxBotix Ultrasonic Sensor

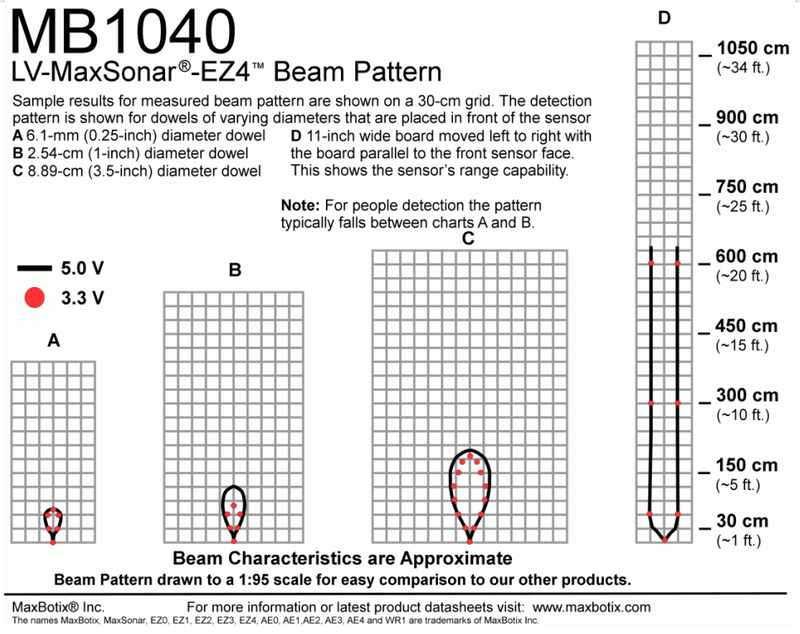

Note: Beam angle diagram for Maxbotix MB1040 is provided.

The actual beam angle changes over the full range. Use the beam pattern for a specific target at any given distance to calculate the beam angle for that target at the specific distance. Generally, smaller targets are detected over a narrower beam angle and a shorter distance. Larger targets are detected over a wider beam angle and a longer range.

Figure:MB1040 Beam Pattern

HC-SR04

- Advantages: Very cost-effective, widely used in educational and hobbyist projects. The narrower beam angle helps with more precise distance detection.

- Disadvantages: Single interface type (only supports GPIO), and an overly narrow beam angle might miss areas that need to be detected.

Maxbotix: EZ4 MB1040

- Advantages: High precision and an extensive measurement range; multi-interface support offers high flexibility; a broad operating temperature range makes it very suitable for harsh environments and industrial settings.

- Disadvantages: The highest price, which might not be the best choice for projects with limited budgets.

Comment