- Stock: In Stock

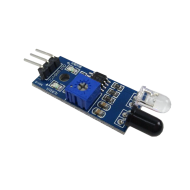

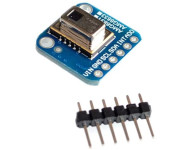

- Model: IR Speed Sensor Module

- Weight: 8.00g

- Dimensions: 32.00mm x 14.00mm x 7.00mm

- SKU: 3751

Introduction

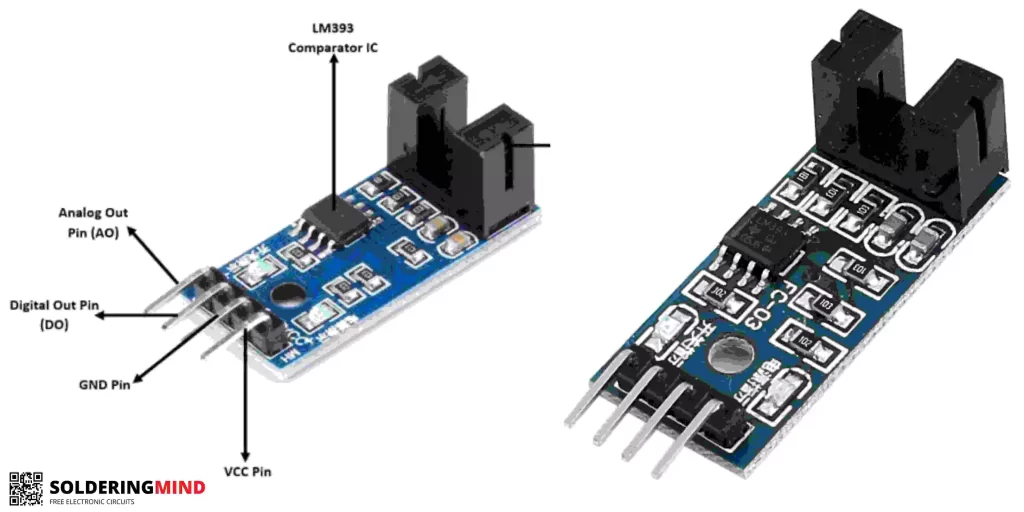

The Infrared Speed Sensor Module is an IR counter that has an IR transmitter and receiver. If any obstacle is placed between these sensors, a signal is sent to the microcontroller. The module can be used in association with a microcontroller for motor speed detection, pulse count, position limit, etc.

Speed-sensing is very important in industrial applications in which process control require precise speed control of production belts to control the rate of manufacturing and also in robotics and autonomous system to determine the exact position of the arm or the tool and its movement. In industry, we use two types of speed sensors: magnetic induction and infrared. This 4 Pin Infrared Speed Sensor Module is used in speed control applications where you need to read the rotation of a disk. It is powered by any of the 3.3V or 5V supplies and gives digital output, which you can easily read with the help of the interrupt function on your microcontroller or development board.

- LM393 Comparator onboard to give digital output

- Low power requirement

- Sensor output is High when the object is detected in the groove; otherwise, Low

- 4 Pins VCC, GND, Dout and Aout

- Working Voltage: 3.3 to 5 VDC

Principle

The speed sensor module is mainly used to detect changes in rotational speed or velocity. When an object passes by the H2010 sensor, it generates a pulse signal. The integrated LM393 comparator inside the module compares this pulse signal with a preset threshold, producing a stable high-level output signal.

The Infrared Speed Sensor Module has 1 H2010 photocell, which consists of a phototransistor and an infrared light emitter packaged in a 10 cm wide black plastic housing.

When operating, the infrared light-emitting diode continuously emits infrared light (invisible light), and the photosensitive triode will conduct if it receives it.

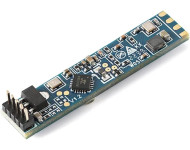

Module Schematic Diagram

Usage

Hardware components

Arduino Uno R4 or R3 board * 1

Infrared Speed Sensor Module * 1

Jumper Wires

Circuit Assembly

Code

Code explanation

Setting up the pins and initializing variables. Here, we define the pins for the motor and the speed sensor. We also initialize variables that will be used to measure and calculate the speed of the motor.

// Define the sensor and motor pins const int sensorPin = 11; const int motorB_1A = 9; const int motorB_2A = 10; // Define variables for measuring speed unsigned long start_time = 0; unsigned long end_time = 0; int steps = 0; float steps_old = 0; float temp = 0; float rps = 0;

Initialization in the

setup()function. This section sets up the serial communication, configures the pins’ modes, and sets the initial motor speed.void setup() { Serial.begin(9600); pinMode(sensorPin, INPUT); pinMode(motorB_1A, OUTPUT); pinMode(motorB_2A, OUTPUT); analogWrite(motorB_1A, 160); analogWrite(motorB_2A, 0); }

Measuring the motor’s speed in the

loop()function. In this segment, the motor’s steps are measured for a duration of 1 second. These steps are then used to calculate the revolutions per second (rps), which is then printed to the serial monitor.millis()returns the number of milliseconds passed since the Arduino board began running the current program.void loop() { start_time = millis(); end_time = start_time + 1000; while (millis() < end_time) { if (digitalRead(sensorPin)) { steps = steps + 1; while (digitalRead(sensorPin)) ; } } temp = steps - steps_old; steps_old = steps; rps = (temp / 20); Serial.print("rps:"); Serial.println(rps); }

IR Speed Sensor Pin Configuration

There is 4 pins are available on the infrared speed sensor module. With the connections of A0, D0, Gnd and Vcc.

| Pin Name | Description |

|---|---|

| VCC | This pin is used to supply power to the sensor. The recommended voltage range is usually between 3-5 volts. |

| GND |

Tags:

Arduino

, Infrared Sensor This is an easy, simple to use Passive IR (PIR) sensor – it only needs a single I/O pin on a microcontroller.or can be easily interfaced with relay or..

KES 350.00 The analog gas sensor - MQ3 is suitable for detecting alcohol, this sensor can be used in a Breathalyser.It has a high sensitivity to alcohol and smal..

KES 600.00 The Raindrop Detection Sensor module is an easy-to-use and low cost drop recognition sensor. The sensor works through a series of exposed parallel tra..

KES 400.00 Features:Input Voltage: DC 3V-5V Flow Rate: 1.2-1.6 L/minOperation Temperature: 80 Deg.COperating Current: 0.1-0.2ASuction Distance: 0.8 meter (M..

KES 300.00 A high quality AC to DC 9V 1000mA wall power supply.These will power most projects that don't require more than 1A of current. Center-positi..

KES 250.00 Manufacturer: DEGSON

Series: DG301

ROHS: YesSpecifications

Number of Positions: 2

Pitch: 5.00mm

Suitable for Wire 12 - 24 AWG

Current Rating..

KES 10.00 Your power supply problems just got SOLVED! This little circuit board may look tiny but inside is a high efficiency DC/DC step-down converter which ca..

KES 500.00 Yes you read that correctly - 10Farad capacitor. This small cap can be charged up and then slowly dissipated running an entire system for hours. Combi..

KES 400.00 This DC/DC step-down voltage converter is based on MP1584, it converts input voltage between 4.5V and 28V into a smaller voltage between 0.8V and 18V,..

KES 250.00 Input voltage range: 6V-32VOutput voltage: default 5V, automatically adjust between 3-12V after triggering fast charge.Output power: maximum 24W (5V@3..

KES 450.00 Arduino R4 Minima - CompatibleEnhanced and improved, the Arduino UNO R4 Minima Compatible is armed with a powerful 32-bit microcontroller courtesy of ..

KES 2,200.00 Use this 3 mm IR Transmitter and Receiver pair to build object sensors, colour sensors, line sensors, distance sensors, etc.Both the transmit..

KES 20.00 This is a pre-wired and waterproofed version of the DS18B20 sensor. Handy for when you need to measure something far away, or in wet conditions. While..

KES 600.00 The adapter interfaces the 1602/1604/2004 LCD to the arduino. It has an output port of 4wires, meaning it frees up the much needed I/O ports of the ar..

KES 200.00 HC-05 is a class-2 bluetooth module with Serial Port Profile , which can configure as either Master or slave. a Drop-in replacement for wired serial c..

KES 800.00 This Infrared obstacle/object detection sensor is super easy to use. It comes with on board potentiometer to adjust the sensitivity. The output is dig..

KES 400.00 This is the latest DS18B20 1-Wire digital temperature sensor from Maxim IC. Reports degrees C with 9 to 12-bit precision, -55C to 125C (+/-0.5C). Each..

KES 150.00 This OLED it is really small, just 0.91”. It is made of 128x32 individual blue OLED pixels, each one is turned on or off by the controller chip. Becau..

KES 500.00 The TMP36 is a low voltage, precision centigrade temperature sensor. It provides a voltage output that is linearly proportional to the Celsius tempera..

KES 600.00 LCD Display Module 1602 - Yellow/Green BacklightTransform your electronics projects with this high-quality 1602 LCD Display Module, designed to provid..

KES 400.00 The Arduino community has come up with the latest revision for the Uno board. It is a beautifully designed board not only from its looks but has some ..

KES 2,000.00 The ATTEN AT-1520 Soldering Wick is a versatile and efficient solution for removing solder from electronic components and PCBs. Its 1.5mm wide braid i..

KES 400.00 Arduino Nano is a surface mount breadboard embedded version with integrated USB. It is a small, complete, and breadboard friendly. It has everything t..

KES 1,500.00 This is an LM2596S DC-DC buck converter step-down power module with high-precision potentiometer, capable of driving a load up to 3A with high efficie..

KES 250.00 The Relay is a digital normally open switch that controls a relay capable of switching much higher voltages and currents than your normal Arduino boar..

KES 150.00 The Analog Capacitive Soil Moisture Sensor measures soil moisture levels by capacitive sensing, rather than resistive sensing like other types of mois..

KES 300.00 These AVR programmers are based on Thomas Fischl's USBasp design and connect to your computer's USB port. Not only are they quite compact (70x20mm), b..

KES 600.00 Double H driver module uses L298N dual full-bridge driver, an integrated monolithic circuit in a 15- lead Multiwatt and PowerSO20 packages. It i..

KES 500.00 Related Products

SKU: 71 A high quality AC to DC 9V 1000mA wall power supply.These will power most projects that don't require more than 1A of current. Center-positi..

KES 250.00

SKU: 129 SpecificationsModel: MB-102

Dimension: 165mm x 55mm x 10mm

Tie Points: 830 Tie Points consists of: 630 Tie-Point Terminal Strip, 200 Tie-Po..

KES 200.00

SKU: 215 A 20cm, 40pcs wire cable connector from dupont. Male to Female terminated...

KES 150.00

SKU: 275 LCD Display Module 1602 - Yellow/Green BacklightTransform your electronics projects with this high-quality 1602 LCD Display Module, designed to provid..

KES 400.00

SKU: 1

Brand: Arduino The Arduino community has come up with the latest revision for the Uno board. It is a beautifully designed board not only from its looks but has some ..

KES 2,000.00

SKU: 3929

Brand: Arduino Arduino R4 Minima - CompatibleEnhanced and improved, the Arduino UNO R4 Minima Compatible is armed with a powerful 32-bit microcontroller courtesy of ..

KES 2,200.00 From Same CategoryThe soil sensor provides rapid access to Nitrogen (N) Phosphorus (P), Potassium (K), soil temperature, humidity, electrical conductivity (EC), and pH ..

KES 15,000.00 The ACS758 Current Sensor IC provides economical and precise solutions for AC or DC current sensing. Typical applications include motor control, load ..

KES 1,200.00 TCRT5000 5-Way Infrared Reflective Sensor 5-Channel Line follower moduleCondition:NewVoltage supply:3.3V / 5VOperating temperature:-40 ° -..

KES 400.00 The A3144 is an integrated Hall effect latched sensor. That’s nice but what does it do? Holding a magnet near the sensor will cause the output pin to ..

KES 100.00 AC Voltage Sensor Module ZMPT101B (Single Phase) is the best for the purpose of the DIY project, where we need to measure the accurate AC voltage with..

KES 500.00 The SDS011 using principle of laser scattering,can get the particle concentration between 0.3 to 10μm in the air. It with digital output and built-in ..

KES 3,800.00 Product Parameters1. Accuracy: + - 2.5°C (4.5°F).2. Maximum frame rate: 10Hz,3. Power supply: 3~5V4. Temperature Measurement Range: 0°C to 80°C (32°F ..

KES 5,000.00 The Analog Capacitive Soil Moisture Sensor measures soil moisture levels by capacitive sensing, rather than resistive sensing like other types of mois..

KES 300.00 Analog electrical conductivity meter V2 is specially used to measure the electrical conductivity of aqueous solution, and then to evaluate the water q..

KES 11,900.00 Conductivity is the reciprocal of an object's resistivity. It represents a material’s ability to pass a current. In a liquid, conductivity is a measur..

KES 35,000.00 This is an Analog pH Meter Kit with industrial real-time online electrode, specially designed for Arduino controllers. It use an industry electrode an..

KES 10,500.00 Gravity: Analog pH Sensor / Meter Pro Kit V2 OverviewDFRobot Gravity: Analog pH meter pro V2 is specifically designed to measure the pH of the solutio..

KES 12,500.00 Analog pH meter V2 is specifically designed to measure the pH of the solution and reflect the acidity or alkalinity. It is commonly used in various ap..

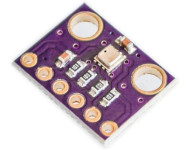

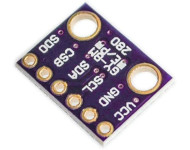

KES 9,500.00 BME280 3.3V:BEM280 technical parameters:Relative humidity range: 0-100%The temperature range is -40 ° C- + 85 ° CHumidity measurement response time: 1..

KES 1,700.00 DescriptionME-BME280 is a Breakout Board featuring a Bosch Sensortec ME280 Temperature, Humidity & Pressure Sensor.The board has selectable I2C ad..

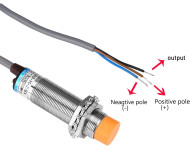

KES 1,000.00 It is a component widely used in automatic control industry for detecting, controlling, and noncontact switching.When proximity switch is close to som..

KES 1,900.00 Are you tired with clicking mechanic button? Try our capacitive touch sensor. Right now we can find touch sensor on most electronic device. So upgrade..

KES 500.00 The CNY70 is a reflective sensor that includes an infrared emitter and phototransistor in a leaded package with a daylight blocking filter.These work ..

KES 250.00 DFRobot released its latest wide range Arduino infrared CO2 sensor, which effective range is up to 0~50000ppm. This sensor is based on non-dispersive ..

KES 10,000.00 Are you trying to make a quick dime from electronics? Why limit yourself to dimes? This coin acceptor will take three different kinds of coin! Whether..

KES 5,000.00 This handy coin validator/acceptor module is just like the ones you've seen in arcades. This model has the cool ability to accept up to 4 different co..

KES 4,000.00 This is the fully integrated Hall Effect based linear current sensor ACS756. It provides economical and precise solutions for AC or DC current sensing..

KES 1,100.00 Accurate sensor to measure AC/DC current up to 20A. The sensor can even measure high AC mains current and is still isolated from the measuring part du..

KES 600.00 Accurate sensor to measure AC/DC current up to 30A. The sensor can even measure high AC mains current and is still isolated from the measuring part du..

KES 600.00 Accurate sensor to measure AC/DC current up to 5A. The sensor can even measure high AC mains current and is still isolated from the measuring part due..

KES 600.00 he Disposable ECG electrode is used for ECG or other biopotential measurements. It is composed of 12 adhesive electrodes, using nonwoven fabric materi..

KES 900.00 Input range: 10A ACOutput range: 5mA ACRatio: 2000: 1Resist: 205Ω ± 5%Non-linear range: 0-55AAccuracy: 0.1Phase shift: <30 'Working temperature: -4..

KES 350.00 Secure your project with biometrics - this all-in-one optical fingerprint sensor will make adding fingerprint detection and verification super simple...

KES 4,500.00 This is the LIDAR-Lite v3, a compact, high-performance optical distance measurement sensor from Garmin™. When space and weight requirements are tight,..

KES 18,800.00 This is an extremely accurate I2C real-time clock (RTC) with crystal compensation, inner chargeable battery. The SD2405AL is available in industrial t..

KES 1,700.00 IC, HALL EFFECT SENSOR, BIPOLAR, TO-92-3

Hall Effect Type: Bipolar

Output Current: 20mA

&n..

KES 200.00 The HC-SR04 ultrasonic sensor uses sonar to determine distance to an object like bats or dolphins do. It offers excellent range accuracy and stable re..

KES 350.00 LD2410B is a high-sensitivity 24GHz human presence status sensing module developed by Hilink Electronics. Its working principle is to use FMCW (Freque..

KES 1,800.00 HX711 Digital Display Electronic Scale Weighing Pressure Module is an integrated module of the pressure sensor test board. The module is con..

KES 1,700.00 This breakout board will solve all your current-monitoring problems. Instead of struggling with a multimeter, you can just use the handy INA169 chip o..

KES 750.00 This breakout board will solve all your power-monitoring problems. Instead of struggling with two multimeters, you can just use the handy INA219B chip..

KES 750.00 INA3221 Three Way I2C Output Current Power Monitor monitors both shunt voltage drops and bus supply voltages, in addition to having programmable conve..

KES 1,000.00 Sensor, 10 mm Sensing, 2000 Hz Frequency Switching, 1.5 mA to 100 mA Current RatingProximity Sensor, M30 x 50, Normally Open, 10 mm, 12 to 48 VDCUL Ce..

KES 3,000.00 Product Name:Infrared photoelectric switch

Model:BKF-DS300C1

Wire Type:3 Wire(Brown, Blue, Black)

Switch Appearance Type: Block Type, Aluminum S..

KES 1,900.00 Infrared proximity sensor made by Sharp. Part # GP2Y0A02YK0F has an analog output that varies from 2.8V at 15cm to 0.4V at 150cm with a supply voltage..

KES 1,200.00 Infrared proximity sensor made by Sharp. Part # GP2Y0A21YK has an analog output that varies from 3.1V at 10cm to 0.4V at 80cm. The sensor has a Japane..

KES 1,500.00 IR sensor tuned to 38KHz, perfect for receiving commands from a TV remote control. Runs at 3V to 5V so it's great for any microcontrollerTo use, c..

KES 200.00 Specification:

Working Power: AC100V~250V, 50/60HZ

Load Power: LED≤40W, Energy Saving≤60W, Incandescent≤100W, Fan≤50W

Standby power 0.0088W

Illumi..

KES 1,200.00 If you've had ideas for a project that depends on the ability to sense different spectrums of visible light and react based on those measurements, the..

KES 1,600.00 This is a waterproof version of HC-SR04 ultrasonic Distance Sensor. It's usage and connections are exactly same as HC-SR04.Features ..

KES 1,400.00 This digital LED meter measures DC voltage from 3.2-30 volts with 1% accuracy. It clear and easy to read. These come in handy for measuring the output..

KES 550.00 Features:Operating temperature: -40°C to 70°C

Bearable pressure: AC250V (50HZ) / min

Per weight: 2g

Size: 1.9 x 0.7 x 1.3cm..

KES 100.00 The product is currently Out-of-Stock. Please enter your details below and we will notify you as soon as the product is available. Name Email Phone Comments  |